Welcome to the 10 Best Hobbyist CNC Plasma Cutters – 2026 Buyer’s Guide. As, you may already know, CNC (Computer Numerical Control) plasma cutting is a process that uses a plasma torch to cut through conductive materials. This technique is based on the use of a high-velocity jet of ionized gas, which conducts electricity from the torch to the workpiece, heating and melting the material. The CNC system automates the movement of the torch, allowing for precise and repeatable cuts. This technology is widely used in industrial applications but has become increasingly accessible for hobbyists.

10 Best Hobbyist CNC Plasma Cutters – 2026 Buyer’s Guide

Eastwood Versa-Cut 4’X4′ CNC Plasma Cutters Table

The Eastwood Versa-Cut 4’x4′ CNC Plasma Cutting Table is a versatile and user-friendly tool designed for both hobbyists and professionals. Its standout feature is the 49″x43″ cutting area, which accommodates standard sheet materials, making it ideal for various projects. The table’s rack-and-pinion design ensures precision with ±0.2mm movement accuracy, while the automatic torch height control adjusts to uneven surfaces, delivering clean and consistent cuts. The integrated CNC controller eliminates the need for a separate computer, and the intuitive LCD interface simplifies operation, even for beginners.

One of the table’s highlights is its robust construction. The steel frame and stepper motors provide durability and stability, ensuring precise gantry movements. The 33-gallon waterbed minimizes sparks and reduces material warping, enhancing safety and cut quality. Additionally, the table is compatible with the Eastwood Versa-Cut 40 Plasma Cutter, which is optimized for this setup, allowing cuts up to 1/4-inch thick in steel, stainless steel, and aluminum. However, users must ensure their plasma cutter has a blowback start, as high-frequency start models are incompatible.

Assembly and setup are straightforward, though some users have noted that the instructions could be clearer. The table comes with all necessary hardware and tools, but having additional tools and assistance can expedite the process. The software integration is another strong point, with support for CAD files via USB and compatibility with Autodesk Fusion 360. The built-in shape library and array options simplify repetitive tasks, making it a practical choice for both simple and complex designs.

Customer reviews highlight the table’s ease of use and value for money. Many users appreciate its professional-grade features at a hobbyist price point, with a 4.8-star average rating. While some have faced challenges with importing external CAM files, the overall feedback emphasizes its reliability and performance. The included lifetime tech support and Eastwood’s three-year warranty further enhance its appeal, providing peace of mind for buyers.

In summary, the Eastwood Versa-Cut 4’x4′ CNC Plasma Cutting Table is a well-rounded solution for precision cutting needs. Its combination of affordability, advanced features, and robust build quality makes it a compelling choice for DIY enthusiasts and small-scale fabricators. While there are minor areas for improvement, such as clearer assembly instructions and software compatibility, its overall performance and user satisfaction make it a worthwhile investment.

For user reviews and to buy online for best pricing and fast delivery – Click Here

Eastwood Versa-Cut 2’X2′ CNC Plasma Cutters Table

The Eastwood Versa-Cut 2’X2′ CNC Plasma Table is a compact yet professional-grade tool designed for home garages and small workshops. Its 24″x24″ cutting area is ideal for creating custom brackets, sign art, and other shapes with precision. The table features a lead screw-driven design, offering ±0.2mm movement accuracy, and includes an automatic torch height control for clean cuts. It operates independently of a PC, with a CNC controller that supports pre-loaded shapes and CAD files via USB. The waterbed, limit switches, and robust aluminum frame enhance its functionality and safety, making it a versatile choice for DIY enthusiasts and professionals alike.

One of the standout features of this plasma table is its user-friendly design. The intuitive color LCD screen and dedicated CNC controller eliminate the need for a separate laptop, making it accessible for beginners while still offering advanced features for experienced users. The table is compatible with Autodesk Fusion 360 for custom designs, and its ability to handle various materials, including aluminum and stainless steel, adds to its versatility. The waterbed, which holds up to 10.4 gallons of fluid, minimizes heat soak and reduces spark and fume hazards, ensuring a safer working environment.

The table’s build quality and design are noteworthy. Its high-strength extruded aluminum frame provides a stable foundation, while the locking casters allow for easy movement and storage. The table is designed to work seamlessly with the Eastwood Versa-Cut 40 Plasma Cutter, although the cutter must be purchased separately. This compatibility ensures optimal performance and ease of use, particularly for those already invested in Eastwood’s product ecosystem. The table’s compact size and 120V power requirement make it suitable for home use without compromising on professional-grade capabilities.

However, there are some limitations to consider. The table does not include a plasma cutter, which must be purchased separately, potentially increasing the overall cost. Additionally, while the table supports advanced CAD software, users may need to invest in additional software like Autodesk Fusion 360 or SheetCAM for more complex projects. These factors, along with the table’s price point, may make it less accessible for casual users or those on a tight budget.

Overall, the Eastwood Versa-Cut 2’X2′ CNC Plasma Table offers a compelling blend of professional features and user-friendly design in a compact package. Its precision, safety features, and compatibility with advanced software make it a valuable tool for serious DIYers and small-scale fabricators. While the initial investment may be significant, the table’s capabilities and build quality justify the cost for those looking to enhance their metalworking projects.

For user reviews and to buy online for best pricing and fast delivery – Click Here

Langmuir Systems – CrossFire CNC Plasma Cutters Table Bundle

The Langmuir Systems CrossFire CNC Plasma Table is a versatile and cost-effective solution for hobbyists and small businesses venturing into CNC plasma cutting. Its compact design and affordability make it an attractive option for those looking to expand their fabrication capabilities without breaking the bank. The machine arrives in a single, well-packaged box, simplifying the assembly process. Users have praised the detailed instructional videos provided by Langmuir Systems, which make setup straightforward even for beginners. The table’s compatibility with various plasma cutters, including the Razorweld 45, adds to its flexibility.

One of the standout features of the CrossFire is its user-friendly operation. The machine integrates seamlessly with Mach-3 software, allowing for intuitive control and programming. The inclusion of a water table helps manage heat and reduce fumes during cutting, enhancing the overall user experience. Additionally, the CrossFire’s ability to handle intricate designs and produce precise cuts has been highlighted as a major advantage, making it suitable for both artistic and industrial applications.

The CrossFire XR model takes the capabilities a step further with advanced features like a dedicated control PC, an industrial touchscreen monitor, and a wireless control pendant. These enhancements improve workflow efficiency and operational flexibility, particularly in larger workshop environments. The inclusion of Langmuir Systems’ Torch Height Control (LS-THC) technology ensures consistent cutting quality, even on uneven materials, by maintaining optimal torch height. With cutting speeds of up to 400 inches per minute, the XR model is designed for rapid production without compromising accuracy.

Despite its many advantages, the CrossFire CNC Plasma Table is not without its limitations. Some users have noted challenges with alignment during assembly, although this is often attributed to user error rather than design flaws. Additionally, while the machine is capable of handling a variety of materials and thicknesses, its performance is ultimately dependent on the plasma cutter used. The lack of an upgrade path from the standard CrossFire to the PRO or XR models may also be a drawback for some users.

Overall, the Langmuir Systems CrossFire CNC Plasma Table offers exceptional value for its price, making it an excellent entry point into CNC plasma cutting. Its combination of affordability, ease of use, and robust features has earned it positive reviews from users across various industries. Whether you’re a hobbyist creating custom designs or a small business owner looking to enhance production capabilities, the CrossFire series provides a reliable and efficient solution.

For user reviews and to buy online for best pricing and fast delivery – Click Here

STV Hurricane 4’x3′ CNC Plasma Cutters Table

The STV Hurricane 4’x3′ CNC Plasma Cutting Table has garnered a mix of positive and critical feedback from users, highlighting its strengths and areas for improvement. Many users praise its affordability and efficiency, noting that it offers excellent value for its price point. The table is often described as a reliable workhorse, capable of handling a variety of cutting tasks with precision. Its modular design and compatibility with popular plasma cutters like Hypertherm are also appreciated, making it a versatile choice for both hobbyists and small businesses.

One of the standout features of the STV Hurricane is its customer support. Numerous reviews emphasize the company’s commitment to assisting customers, with responsive and knowledgeable staff who go above and beyond to resolve issues. This level of support has been a deciding factor for many buyers, especially those new to CNC plasma cutting. The availability of tutorials and a supportive community further enhances the user experience.

However, some users have pointed out design limitations, particularly with the modular tables. Concerns about the sturdiness of the bolt-together frame and the performance of the direct drive system at high speeds have been noted. These issues may affect cut quality on thinner materials, especially at faster feed rates. For those requiring a more robust setup, the welded frame and gear reduction system of the Pro models are recommended.

The software included with the STV Hurricane receives mixed reviews. While it is user-friendly and sufficient for basic operations, some users find it lacking in advanced features. This has led to recommendations for third-party software like SheetCam for more complex projects. Additionally, the learning curve for new users can be steep, but the company’s support team helps mitigate this challenge.

Overall, the STV Hurricane 4’x3′ CNC Plasma Cutting Table is a solid choice for those seeking an entry-level or mid-range plasma cutting solution. Its combination of affordability, customer support, and functionality makes it a popular option, though potential buyers should carefully consider their specific needs and the table’s limitations before making a purchase.

For user reviews and to buy online for best pricing and fast delivery – Click Here

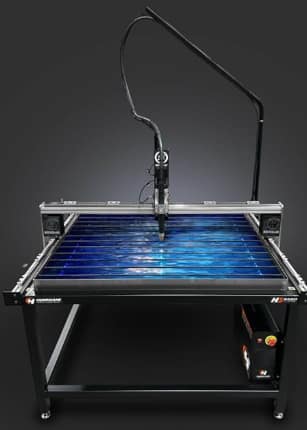

Eastwood Versa Cut 4X8 CNC Plasma Cutters Table

The Eastwood Versa Cut 4X8 CNC Plasma Table is a professional-grade tool designed for precision metal cutting, catering to both hobbyists and professionals. Its standout feature is the large 4×8 cutting area, which accommodates substantial sheet materials, making it ideal for large-scale projects. The table integrates a dedicated CNC controller, eliminating the need for an external PC, and supports file loading via USB, offering convenience and ease of use. Additionally, the system includes the Versa-Cut 40 Plasma Cutter, specifically designed to work seamlessly with the table, ensuring compatibility and efficiency.

Users have praised the table for its robust build and cutting accuracy, which is rated at ±0.5mm. The waterbed feature, measuring 52.5″ x 52.8″, helps manage cutting fluid and reduces slag, enhancing the overall cutting experience. However, some users have noted that the assembly process can be challenging due to unclear instructions, and the manual lacks detailed guidance on optimizing cut settings. Despite these minor drawbacks, the table is considered a reliable entry-level option for those venturing into CNC plasma cutting.

The plasma cutter itself operates on dual voltage (120V and 240V), offering flexibility for various power setups. It can cut materials up to 3/8-inch thick, making it suitable for medium-duty fabrication tasks. The system’s intuitive touch screen interface and pre-loaded shapes simplify the cutting process, even for beginners. Advanced users can also import CAD files for more intricate designs, expanding the table’s versatility.

Customer reviews highlight the table’s value for money, with many appreciating its performance at a relatively affordable price point compared to other professional-grade CNC plasma tables. The included customer support and warranty further add to its appeal, ensuring peace of mind for buyers. However, some users have expressed concerns about the availability and cost of consumables, which could impact long-term usability.

In summary, the Eastwood Versa Cut 4X8 CNC Plasma Table is a well-rounded tool that balances affordability with functionality. While it may not cater to heavy industrial use, it is an excellent choice for hobbyists and small-scale fabricators looking for precision and reliability in their metalworking projects. With its user-friendly features and robust performance, it stands out as a valuable addition to any workshop.

For user reviews and to buy online for best pricing and fast delivery – Click Here

Eastwood Versa-Cut 5’x5′ CNC Plasma Cutters Table

The Eastwood Versa-Cut 5’x5′ CNC Plasma Cutter Table is a versatile and user-friendly tool designed for both hobbyists and professionals. Its standout feature is the large cutting area, which accommodates standard pre-cut sheet materials, making it ideal for various projects. The table’s robust steel frame ensures stability, while the rack-and-pinion design and automatic torch height control deliver precise cuts with ±0.2mm accuracy. Additionally, the intuitive color LCD interface and USB compatibility simplify operation, even for beginners.

One of the key advantages of this plasma cutter is its dual-voltage capability, allowing it to operate on both 120V and 240V power sources. This flexibility makes it suitable for a wide range of environments, from home workshops to professional settings. The included Versa-Cut 40 Plasma Cutter is specifically designed for this table, offering clean and precise cuts on materials like steel, stainless steel, and aluminum up to 1/4-inch thick. The long 20-foot torch cable adds convenience, enabling users to work on larger projects without repositioning the machine.

However, the Eastwood Versa-Cut does have some limitations. While it excels in cutting thinner materials, users have noted that cutting thicker materials requires slower travel speeds and can lead to increased wear on consumables. Additionally, the included instruction manual has been criticized for its lack of detailed guidance, which may pose a challenge for first-time users. Despite these drawbacks, the machine’s overall performance and affordability make it a popular choice among hobbyists.

The table’s waterbed feature, capable of holding up to 33 gallons of cutting fluid, is another highlight. This not only helps in reducing heat and minimizing warping but also keeps the workspace cleaner by trapping debris. The locking casters provide mobility, allowing users to move and store the table conveniently when not in use. These features, combined with Eastwood’s three-year warranty, add to the product’s appeal and reliability.

In conclusion, the Eastwood Versa-Cut 5’x5′ CNC Plasma Cutter Table offers a compelling mix of precision, versatility, and affordability. While it may not match the performance of high-end industrial models, it provides excellent value for its price point, making it a solid investment for hobbyists and small-scale professionals looking to enhance their cutting capabilities.

For user reviews and to buy online for best pricing and fast delivery – Click Here

STV Sparx 4×8 CNC Plasma Cutters Table

The STV Sparx 4×8 CNC Plasma Table is a robust and versatile tool designed for both industrial and small business applications. Its modular design allows for easy assembly and customization, making it accessible for users with varying levels of experience. The table features a cutting envelope of 8 feet by 4 feet, capable of handling materials up to 1.5 inches thick. Its sturdy frame and advanced stepper motor system ensure precision and durability, while the included water table minimizes dust and heat-related warping during operation.

One of the standout features of the Sparx 4×8 is its user-friendly software, MyPlasmCNC, which supports various file types and includes a library of over 1,000 free cut files. The software is designed for beginners but offers enough functionality for more advanced users. Additionally, the table is equipped with automatic torch height control, collision detection, and material sensing, ensuring consistent and high-quality cuts. Optional upgrades, such as a gear reduction motor system and automatic homing kit, further enhance its capabilities.

Customer feedback highlights the table’s reliability and the exceptional support provided by STV CNC. Many users have praised the company’s responsive technical assistance and active online community, which offers a wealth of shared knowledge and resources. The table’s affordability, combined with its industrial-grade features, makes it a popular choice among hobbyists and professionals alike.

However, some users have noted a learning curve, particularly for those new to CNC plasma cutting. While the assembly process is straightforward, it requires attention to detail to ensure optimal performance. Additionally, the table’s modular design, while convenient for shipping and setup, may not be as rigid as fully welded alternatives. Despite these minor drawbacks, the Sparx 4×8 is widely regarded as a cost-effective and high-performing plasma table.

In summary, the STV Sparx 4×8 CNC Plasma Table offers a compelling blend of affordability, functionality, and support. Its robust design and advanced features make it suitable for a wide range of applications, from custom fabrication to industrial production. With its strong community backing and excellent customer service, the Sparx 4×8 is a reliable investment for anyone looking to enhance their metalworking capabilities.

For user reviews and to buy online for best pricing and fast delivery – Click Here

Baileigh PT-105HD-V2 5×10 CNC Plasma Cutters Table

The Baileigh PT-105HD-V2 5×10 CNC Plasma Table is a robust and versatile machine designed for high-volume industrial applications. Its heavy-duty steel frame and 5′ x 10′ cutting area make it ideal for handling full-size sheets of steel, aluminum, and other materials. The table is equipped with a dual-side drive system and linear guide rails, ensuring smooth motion and precise cuts. Additionally, the inclusion of a water table minimizes dust, smoke, and heat distortion, contributing to cleaner and safer operations.

One of the standout features of the PT-105HD-V2 is its user-friendly Windows-based CNC controller, which supports DXF files for seamless design integration. The machine comes with BobCAD-CAM Express software, allowing users to design and program projects on any computer and transfer them via USB. The console also includes a pre-loaded library of shapes that can be resized and altered directly at the table, eliminating the need for additional software.

The table’s Panasonic brushless servo motors and servo motion controllers provide reliable and efficient gantry movement. Its high gantry design offers excellent visibility for adjustments, while the automatic height detection on the Z-axis ensures consistent cuts, even on uneven materials. The machine’s industrial-grade construction, including Hiwin square rails with wipers to keep out debris, enhances durability and reduces maintenance needs.

Ease of use is another highlight, as the PT-105HD-V2 arrives nearly fully assembled, saving time and effort during setup. It operates on 220-volt single-phase power, making it accessible for most industrial settings. The gantry’s ability to move out of the way during loading reduces the risk of damage, further showcasing the thoughtful design of this plasma table.

Overall, the Baileigh PT-105HD-V2 is a powerful and reliable CNC plasma table that combines precision, durability, and user-friendly features. Its robust construction and advanced capabilities make it a valuable asset for fabrication shops and industrial environments seeking high-quality plasma cutting solutions.

For user reviews and to buy online for best pricing and fast delivery – Click Here

STV Sparx 2×4 CNC Plasma Cutters Table

The STV Sparx 2×4 CNC Plasma Cutting Table is a robust and versatile tool designed for precision and efficiency in metal fabrication. Its modular, bolt-on frame supports up to a 1-inch steel plate, making it suitable for both light and heavy-duty applications. The table features a cutting envelope of 2 feet by 4 feet, with a sturdy aluminum gantry and advanced stepper motor systems for smooth operation. It also includes a water pan for wet cutting, interchangeable slats, and a user-friendly assembly process that takes approximately 2-3 hours. The table is backed by a one-year warranty and lifetime technical support, ensuring reliability and peace of mind for users12.

One of the standout features of the Sparx 2×4 is its advanced automation capabilities. It comes equipped with a Torch Height Control (THC) system, collision sensors, and ohmic material detection, which collectively enhance cutting precision and safety. The table also includes a downloadable MyPlasm CNC software, which supports various file types and offers over 1,000 free cut files. This makes it an excellent choice for both beginners and experienced fabricators looking for a comprehensive solution1.

However, some users have noted potential drawbacks. The modular design, while convenient for shipping and assembly, may lack the sturdiness of welded-frame alternatives. Additionally, the direct-drive stepper motors might struggle with high-speed cuts on thinner materials, potentially affecting cut quality. Despite these concerns, the table’s affordability and feature set make it a competitive option in its price range2.

Customer feedback highlights the company’s strong technical support and community resources. Buyers gain access to a private Facebook group with over 2,300 members, offering a platform for sharing tips, settings, and project ideas. The company also provides detailed instructional videos and responsive customer service, which many users have praised for its professionalism and helpfulness2.

In summary, the STV Sparx 2×4 CNC Plasma Cutting Table is a well-rounded option for small to medium-scale fabrication projects. Its combination of advanced features, user-friendly software, and robust support network make it a valuable investment for hobbyists and professionals alike. While it may not be the best fit for high-speed industrial applications, its versatility and affordability ensure it remains a popular choice in the CNC plasma cutting market

For user reviews and to buy online for best pricing and fast delivery – Click Here

Factors to Consider When Buying | 10 Best Hobbyist CNC Plasma Cutters – 2026

Investing in a CNC plasma cutting table can transform your workshop’s capabilities, boosting productivity and precision. These powerful machines automate the cutting process for conductive metals, enabling intricate designs and rapid production. However, with a wide range of models and features available, choosing the right one can feel overwhelming. This guide will walk you through the essential factors to consider, helping you select a machine that aligns with your specific needs and budget.

We will explore the key considerations, from the physical size of the table to the software that drives it. Understanding these elements will empower you to make a confident and informed purchasing decision. By the end of this post, you’ll have a clear roadmap for evaluating different CNC plasma tables and finding the perfect fit for your operation.

Table Size and Workspace Integration

The first factor to evaluate is the physical size of the machine. Your choice here impacts not only the size of the material you can work with but also how the machine fits into your existing workspace.

Material Dimensions

Consider the typical dimensions of the metal sheets you plan to cut. Common sheet sizes are 4×8 ft, 5×10 ft, and 6×12 ft. Your table must be large enough to accommodate these materials. Buying a table that is slightly larger than your most common workpiece size provides flexibility and prevents you from being limited in the future. A larger table can also help you process multiple smaller jobs at once, improving efficiency.

Shop Floor Footprint

A CNC plasma table requires more space than just its cutting area. You need to account for the machine’s full footprint, including the control cabinet, fume extraction system, and space for loading and unloading materials. Ensure you have adequate clearance around the machine for safe operation and routine maintenance. Measure your available floor space carefully and compare it to the manufacturer’s specifications. Don’t forget to consider vertical clearance, especially if you plan to use an overhead crane for loading heavy plates.

Cutting Capacity and Power Source

The heart of any plasma cutter is its power source, which determines the machine’s cutting capacity. This refers to the type and thickness of metal it can effectively sever.

Material Type and Thickness

What metals will you be cutting? Steel, stainless steel, and aluminum have different cutting requirements. The power source, measured in amps, directly correlates to the thickness of the metal it can handle. For instance, a lower-amperage system might be sufficient for thin-gauge sheet metal used in HVAC ductwork, while cutting thick steel plates for heavy equipment manufacturing will require a high-amperage industrial system.

Review the manufacturer’s specifications for two key ratings:

Rated Cut Capacity: The thickest material the machine can cut cleanly and consistently at an optimal speed.

Severance Capacity: The absolute maximum thickness the machine can cut through, though typically at a much slower speed and with a rougher edge quality.

Always choose a machine with a rated cut capacity that comfortably exceeds the thickest material you plan to cut regularly. Pushing a machine to its severance limit constantly will lead to poor cut quality and premature wear on consumables.

Duty Cycle

The duty cycle is the percentage of time a machine can operate at its maximum rated output within a 10-minute period without overheating. A 60% duty cycle means the machine can cut for six minutes straight before needing a four-minute cool-down period. For high-production environments, a machine with a 100% duty cycle is ideal, as it can run continuously without interruption. For smaller shops or hobbyists, a lower duty cycle may be perfectly acceptable.

Software and Control System

The software and control system are the brains of the CNC table, translating your digital designs into precise physical movements. Ease of use, compatibility, and features are critical.

CAD/CAM Software

Your workflow will typically involve two types of software:

CAD (Computer-Aided Design): Used to create or edit the 2D drawings of the parts you want to cut.

CAM (Computer-Aided Manufacturing): Used to convert the CAD drawing into G-code, which contains the toolpaths and cutting instructions for the CNC controller.

Some manufacturers offer integrated CAD/CAM software packages with their tables, which can simplify the workflow. Check if the provided software is intuitive and has the features you need. If you already use specific CAD software like AutoCAD or SolidWorks, ensure the machine’s CAM software can easily import your existing file types (e.g., DXF or DWG).

CNC Controller

The CNC controller is the hardware interface that reads the G-code and operates the machine’s motors and plasma torch. A user-friendly controller with a clear interface can significantly reduce the learning curve and minimize operator errors. Look for features like a large, easy-to-read screen, industrial-grade buttons, and the ability to easily adjust settings mid-cut. Some advanced controllers offer features like automatic height control and collision detection, which can improve cut quality and protect your investment.

Durability and Build Quality

A CNC plasma table is a significant investment, so you want a machine built to last. The overall construction and quality of components play a major role in the machine’s accuracy, reliability, and lifespan.

Frame and Gantry Construction

Look for a table with a heavy, welded steel frame. A robust frame minimizes vibrations during cutting, which is essential for maintaining accuracy and achieving a smooth edge finish. The gantry, which moves the torch across the work area, should also be rigid and well-engineered. High-quality components like precision-ground linear rails and helical rack-and-pinion drive systems contribute to smoother, more accurate motion compared to less expensive alternatives.

Component Quality

Pay attention to the quality of smaller components, as they are crucial for long-term reliability. This includes the motors, drive systems, bearings, and cables. Reputable manufacturers use industrial-grade components designed for continuous use in harsh workshop environments. Ask the supplier about the brands of key components and their service life expectations.

Support, Service, and Total Cost of Ownership

The initial purchase price is only one part of the equation. Consider the long-term costs and the support you will receive from the manufacturer or distributor.

Initial Cost vs. Long-Term Value

While it can be tempting to choose the cheapest option, a low-quality machine can cost more in the long run due to frequent downtime, wasted materials, and higher maintenance needs. Balance the initial investment against the machine’s features, build quality, and expected lifespan. Obtain quotes from multiple suppliers and compare what is included with each package—some may include software, training, and a starter set of consumables.

Training and Technical Support

Effective training is crucial for getting the most out of your new machine. Does the supplier offer on-site training for you and your team? What kind of technical support is available after the sale? Reliable, accessible support via phone or email can be invaluable when you encounter an issue and need to get your machine back up and running quickly. Check reviews and ask for references to gauge the quality of a company’s customer service.

Consumables and Maintenance

Plasma cutting consumes parts like nozzles, electrodes, and swirl rings. The cost and availability of these consumables contribute to the machine’s operating expenses. Investigate the price and lifespan of consumables for the models you are considering. Additionally, understand the routine maintenance requirements to keep the machine in optimal condition.

Making a well-researched decision is the key to a successful purchase. By carefully evaluating the table size, cutting capacity, software, build quality, and overall cost, you can select a CNC plasma table that will serve as a reliable and profitable asset for your business for years to come.

Conclusion: 10 Best Hobbyist CNC Plasma Cutters 2026

We hope this 10 Best Hobbyist CNC Plasma Cutters | 2026 Buyer’s Guide helped you take one step closer to realizing your vision for the creations you wish to make. CNC plasma cutters have become indispensable tools for hobbyists looking to explore metalworking. With the right cutter, you can achieve precision cuts and bring your designs to life. Whether you’re a beginner or an experienced hobbyist, there’s a CNC plasma cutter that suits your needs and budget. Consider the options listed above to find the perfect machine for your projects.