When it comes to fabricating metal parts and products, there is no better way to do it than with a CNC plasma table. These machines are extremely precise and can create some of the most intricate designs possible. In this article, we will explore some of the best CNC plasma tables – 2026. We will also discuss some of the factors you should consider when purchasing one of these machines.

When it comes to purchasing a CNC plasma table, there are several things you’ll want to keep in mind. Here are four key factors to consider:

1. Cutting area

2. Reliability and support

3. Ease of use

4. Budget

Let’s take a closer look at each of these factors:

1. Cutting area: One of the most important things to consider is the size of the cutting area. You’ll want to make sure that the table you purchase can accommodate whatever projects you have planned. If you’re planning on doing a lot of large-scale projects, for example, you’ll need a table with a large cutting area. But if you mostly work on smaller projects, you can get away with a smaller table.

2. Reliability and support: Another important consideration is the reliability and support of the CNC plasma table you purchase. You’ll want to make sure that you’re buying from a reputable company that offers good customer service and technical support. That way, if you have any problems with your table, you know you can count on them to help you out.

3. Ease of use: Another factor to consider is how easy the table is to use. You’ll want to make sure that it’s user-friendly and that you won’t have any trouble operating it. If you’re not comfortable using a certain feature, or if you find the controls confusing, it’s probably not the right table for you.

4. Budget: Finally, you’ll need to consider your budget when purchasing a CNC plasma table. There are a wide range of prices out there, so it’s important to find one that fits within your budget. But don’t sacrifice quality for price – make sure you’re getting a good value for your money.

5 Best CNC Plasma Tables 2026

Baileigh PT-22 CNC Plasma Cutting Table

The Baileigh PT-22 CNC Plasma Cutting Table is a compact and versatile machine designed for small-scale fabrication projects. With a 2 ft. x 2 ft. working area, it is ideal for users with limited space. The table comes fully assembled, saving users the hassle of setup and alignment. It operates on a standard 110V power supply, making it accessible for most workshops. Additionally, the PT-22 includes a water bath to reduce dust and warping during cuts, as well as two torch holders—one for automated systems and another for handheld torches—offering flexibility in operation.

One of the standout features of the PT-22 is its user-friendly design software, which allows users to create and transfer designs via USB. The inclusion of a handheld pendant with jog controls for the X and Y axes, along with program start and stop functions, enhances its ease of use. However, some users have noted that the table’s build quality may not meet the standards of higher-end models, with concerns about alignment and durability over time. This has led to mixed reviews, with some users praising its affordability and functionality, while others compare it unfavorably to more robust alternatives like Torchmate.

The PT-22’s affordability is a significant draw, but it comes with trade-offs. Some users have reported issues with the quality of welds and adjustments, likening it to budget-friendly tools from brands like Harbor Freight. Despite these criticisms, the table’s compact size and straightforward operation make it a practical choice for hobbyists or small businesses looking to cut brackets, tabs, and other components without investing in a larger, more expensive machine.

In conclusion, the Baileigh PT-22 CNC Plasma Cutting Table is a cost-effective solution for light-duty cutting tasks, particularly for those with space and budget constraints. While it may not offer the precision or durability of premium models, its ease of use and included features make it a viable option for entry-level users or small-scale operations. Prospective buyers should weigh its affordability against potential limitations in build quality and performance.

For user reviews and to buy online for best pricing and fast delivery – Click Here

Langmuir Systems CrossFire CNC Plasma Table

The Langmuir Systems CrossFire CNC Plasma Table is a versatile and cost-effective solution for hobbyists and small businesses venturing into CNC plasma cutting. Priced competitively, it offers a compact design with a cutting area suitable for various projects, from intricate designs to functional components. The assembly process is straightforward, aided by detailed instructional videos, making it accessible even for beginners. Users have praised its intuitive operation, supported by the Mach-3 software, and the seamless integration with compatible plasma cutters like the Razorweld 45.

One of the standout features of the CrossFire is its robust build quality, which ensures durability and precision. The addition of a water table helps in managing heat and reducing fumes during operation, enhancing the overall user experience. The machine’s ability to handle different materials and thicknesses with consistent accuracy makes it a reliable choice for both artistic and industrial applications. Furthermore, the availability of add-ons like the Torch Height Control (THC) module expands its capabilities, catering to more advanced cutting needs.

Customer feedback highlights the importance of regular maintenance to ensure optimal performance. Cleaning the rails and inspecting cables are simple yet crucial tasks to prevent operational hiccups. Users have also shared tips for enhancing functionality, such as adding casters for mobility and using pressure regulators for better cutting consistency. These insights reflect the active and supportive community around the CrossFire, which is a valuable resource for troubleshooting and maximizing the machine’s potential.

In summary, the Langmuir Systems CrossFire CNC Plasma Table strikes a balance between affordability and functionality, making it an excellent entry point into CNC plasma cutting. Its user-friendly design, coupled with robust performance and a supportive community, ensures that it meets the needs of both beginners and experienced users. While it may require some hands-on maintenance and occasional upgrades, its overall value and versatility make it a worthwhile investment for those looking to enhance their fabrication capabilities.

For user reviews and to buy online for best pricing and fast delivery – Click Here

Eastwood Versa-Cut 2’X2′ CNC Plasma Table

The Eastwood Versa-Cut 2’X2′ CNC Plasma Table is a compact yet professional-grade tool designed for home garages and small workshops. Its 24″x24″ cutting area is ideal for creating custom brackets, sign art, and other shapes with precision. The table features a lead screw-driven design, offering ±0.2mm movement accuracy, and includes an Automatic Torch Height Control for clean cuts. The CNC Cut Controller operates independently of a PC, with 50 preloaded shapes and compatibility with CAD files via USB. Additional features like limit switches and a waterbed enhance safety and cutting quality, making it a versatile choice for DIY enthusiasts and professionals alike.

One of the standout aspects of the Versa-Cut is its user-friendly design. The intuitive color LCD screen and dedicated CNC controller eliminate the need for a separate laptop, making it accessible for beginners while still offering advanced features for experienced users. The table is built with a high-strength extruded aluminum frame, ensuring durability and stability during operation. It also includes locking casters for easy mobility and storage, further emphasizing its suitability for home use.

The table is specifically designed to work seamlessly with the Eastwood Versa-Cut 40 Plasma Cutter, which is sold separately. This pairing allows for precise cuts in materials like steel, stainless steel, and aluminum up to 1/4-inch thick. The plasma cutter operates on both 120V and 240V, offering flexibility for various power setups. However, users should note that only plasma cutters with a blowback start are compatible, as high-frequency start machines may damage the table’s electronics.

Overall, the Eastwood Versa-Cut 2’X2′ CNC Plasma Table offers a robust combination of precision, ease of use, and safety features. Its compact size and professional capabilities make it a valuable addition to any small workshop or garage. While the initial investment may be significant, the table’s versatility and performance justify the cost for those serious about metal fabrication and custom projects.

For user reviews and to buy online for best pricing and fast delivery – Click Here

STV Hurricane 4’x3′ CNC Plasma Table

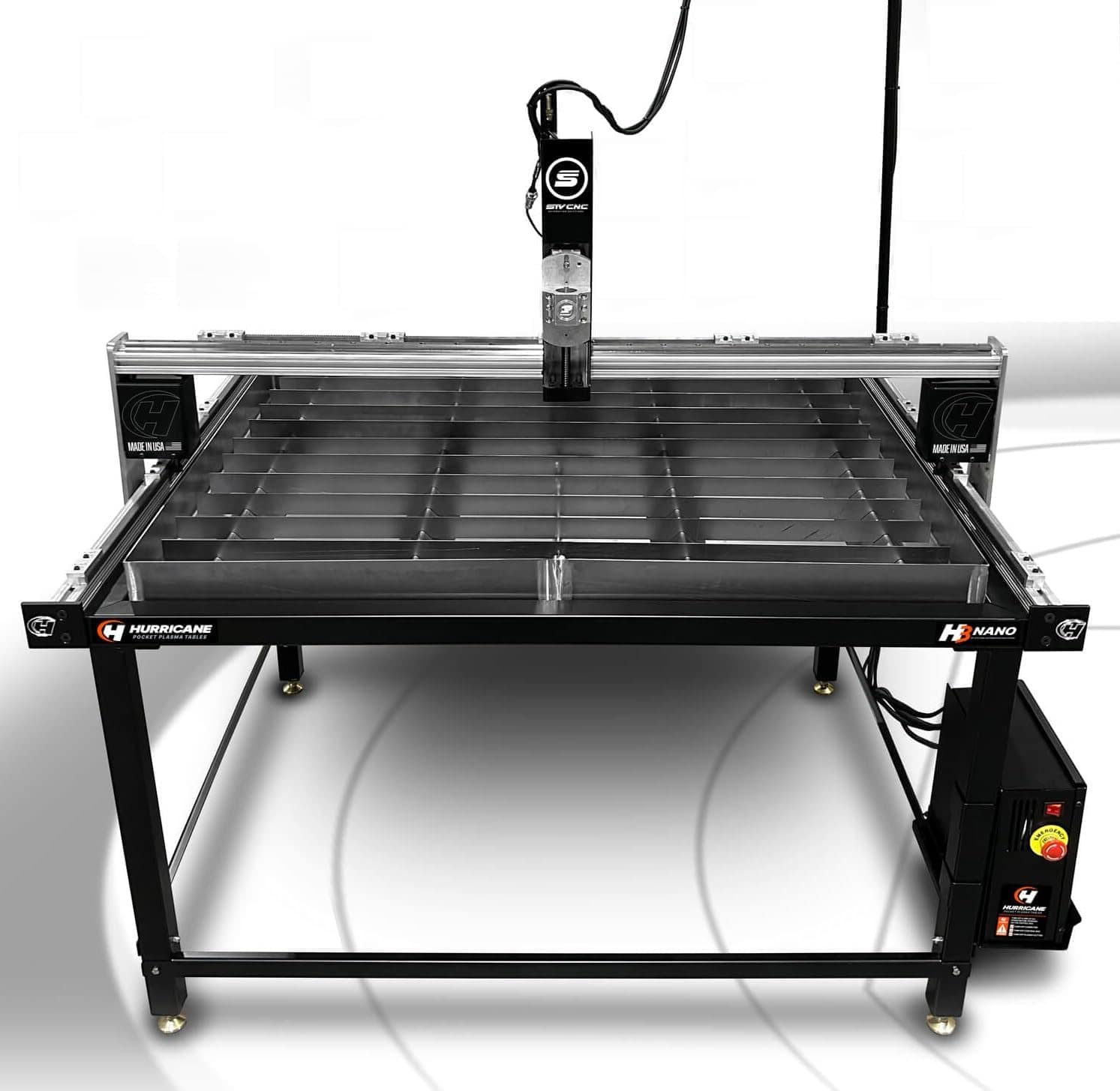

The STV Hurricane 4’x3′ CNC Plasma Table, also known as the Hurricane H3 NANO, is a compact yet robust entry-level plasma cutting solution designed for precision and efficiency. Manufactured in the USA, this table features a welded tube frame capable of supporting up to a 1-inch steel plate, making it suitable for both hobbyists and small-scale industrial applications. Its cutting envelope of 48″ x 35″ is complemented by a space-saving design, with dimensions of 61″ x 85″ x 51″. The table includes advanced features such as a floating head with torch height control, magnetic breakaway safety mechanisms, and a linear guide assembly for smooth operation.

One of the standout aspects of the Hurricane H3 NANO is its user-friendly Optimum CNC control system, which comes pre-installed on a palm-sized Mini PC. This system offers free software updates and access to a private owner’s community for sharing skills and settings. The table also includes homing switches, a collision switch with ohmic sensing, and adjustable leveling feet for enhanced stability and precision. Additionally, the modular design allows for easy assembly and maintenance, with features like interchangeable slats and a single water pan for wet or dry cutting operations.

Customer feedback highlights the table’s reliability and the exceptional support provided by STV CNC. Users have praised the company’s responsive technical assistance and the active online community, which fosters collaboration and troubleshooting. The table’s affordability, combined with its high-quality build and performance, makes it a popular choice among fabricators and metalworkers. However, some users have noted a learning curve with the software and the need for additional equipment, such as a plasma cutter and air compressor, which are sold separately.

Overall, the STV Hurricane 4’x3′ CNC Plasma Table offers a compelling blend of functionality, durability, and support, making it an excellent investment for those looking to enhance their metalworking capabilities. Its combination of advanced features and accessible pricing positions it as a strong contender in the entry-level CNC plasma table market.

For user reviews and to buy online for best pricing and fast delivery – Click Here

SHUANGBING WELDER Portable CNC Machine with THC for Oxyfuel and Plasma Cutting

The SHUANGBING WELDER Portable CNC Machine is a versatile and compact tool designed for precision cutting in both oxyfuel and plasma applications. With a cutting area of 63 x 98 inches, it is suitable for a variety of materials and thicknesses, making it a valuable asset for small workshops, hobbyists, and metal fabricators. Its portability and lightweight design allow for easy transportation and setup, making it ideal for on-site jobs. The machine’s construction, featuring high-quality materials like painted steel and aluminum alloy track rails, ensures durability and reliability for heavy-duty tasks.

One of the standout features of this CNC machine is its Torch Height Control (THC) technology, which maintains consistent cutting performance even on uneven surfaces. The intuitive digital control system simplifies operation, enabling users of varying skill levels to achieve professional-quality results. Additionally, the machine supports both flame and plasma cutting, offering flexibility for different cutting needs. The flame cutting assembly can handle thicknesses up to 7.87 inches, while the plasma cutting capability depends on the matching plasma source, providing speed and precision.

Despite its many advantages, the SHUANGBING WELDER Portable CNC Machine has some limitations. It is not designed for large-scale industrial use or high-volume production due to its limited cutting dimensions and power. Beginners may also find it challenging to operate without prior experience with CNC machines. However, for small-scale projects and workshops, it offers an affordable and efficient solution for intricate designs and precision cutting.

In conclusion, the SHUANGBING WELDER Portable CNC Machine is a well-rounded tool that combines portability, versatility, and precision. Its compact design, user-friendly interface, and robust construction make it a great choice for small workshops and hobbyists. While it may not be suitable for large-scale industrial applications, it excels in delivering high-quality results for smaller, detailed projects.

For user reviews and to buy online for best pricing and fast delivery – Click Here

The Benefits of a CNC Plasma Table

The benefits of a CNC plasma table are many and varied. In addition to the obvious advantages of increased accuracy and precision, a CNC plasma table can also offer significant increases in productivity. The ability to quickly and easily create complex shapes and designs is a major advantage of using a CNC plasma table, as is the fact that the machine can be operated with very little operator input. This means that businesses can save time and money by investing in a CNC plasma table.

There are several other benefits of using a CNC plasma table, including the fact that the machines are very versatile. They can be used to create both small and large parts, and they can be used for a variety of different applications. This makes them an ideal choice for businesses of all sizes.

Another advantage of using a CNC plasma table is that they are relatively easy to maintain. The machines do not require a lot of upkeep, and they can be easily repaired if something goes wrong. This makes them a much more cost-effective option than traditional methods of manufacturing.

If you are considering investing in a CNC plasma table, then it is important to weigh up all of the benefits before making a decision. The benefits listed above are just some of the reasons why these machines are so popular. When you take into account all of the advantages, it is easy to see why a CNC plasma table could be the perfect choice for your business.

How to use a CNC Plasma Table

If you’re looking to get the most out of your CNC plasma table, there are a few things you need to keep in mind. Here are some tips on how to use a CNC plasma table:

1. Make sure your material is properly secured. This will help prevent the material from moving or shifting during the cutting process, which can result in inaccuracies.

2. Use appropriate cutting speeds and settings for your material. If you’re unsure, consult your machine’s manual or a professional for guidance.

3. Keep the torch at a consistent height above the material. This will help ensure accurate cuts and minimize wear on the torch tip.

4. Use proper gas pressure and flow rates for your material. Again, consult your machine’s manual or a professional for guidance if you’re unsure.

5. Make sure your work area is well-ventilated. Cutting with a CNC plasma table produces fumes that can be harmful if inhaled.

Following these tips will help you get the most out of your CNC plasma table and ensure accurate, consistent cuts.

The Different Types of CNC Plasma Tables

CNC plasma tables are available in a variety of sizes and specifications to suit different needs. The most common types are:

– Compact CNC plasma tables: These are smaller machines that are typically used for light-duty applications such as hobby work or prototyping.

– Commercial CNC plasma tables: These are larger machines that are designed for industrial use. They can handle heavy materials and have greater cutting power than compact CNC plasma tables.

– Custom CNC plasma tables: These are made to order according to the specific requirements of the customer. This allows for greater flexibility in terms of size and specification, but also means that custom CNC plasma tables can be more expensive than other types.

What to Know Before Purchasing a CNC plasma Table

There are a few things you should know before purchasing a CNC plasma table.

Firstly, you need to consider the size of the table. The table needs to be big enough to accommodate your project, but not too big that it becomes unwieldy.

Secondly, you need to think about power requirements. Plasma tables require a lot of power, so make sure you have the right setup in place.

Thirdly, you need to consider the software. The software is what controls the table and allows you to create your projects. Make sure you choose a software that is easy to use and has all the features you need.

How to Set Up Your CNC Plasma Table

If you want to know how to set up your CNC plasma table, there are a few things that you need to do first. You need to make sure that you have all of the necessary equipment and software installed on your computer. You also need to make sure that you have a good understanding of the G-code language.

2. The next thing you need to do is find a place to set up your table. You need to make sure that the area is well lit and free of any objects that could obstruct the view of the table. It is also important to make sure that the area is large enough for you to comfortably move around in.

3. Once you have found a suitable location, the next thing you need to do is set up your table. You need to make sure that the legs are securely attached to the table and that the table is level. If the table is not level, it could cause problems with the cutting process.

4. After the table is set up, you need to install the software that will be used to control the CNC plasma cutter. This software is typically provided by the manufacturer of the CNC plasma cutter.

5. The next step is to connect the power supply to the CNC plasma cutter. Make sure that all of the connections are tight and secure.

6. Finally, you need to connect the air supply to the CNC plasma cutter. The air supply is typically provided by a compressor. Make sure that the air pressure is set to the correct pressure for the CNC plasma cutter.

7. Once all of the connections are made, you are ready to start cutting. Make sure that you have a good understanding of the G-code language before starting the cutting process. If you do not understand the G-code language, you could damage the table or the cutter.

8. When you are ready to start cutting, select the appropriate file from the software and load it into the CNC plasma cutter.

9. Press the start button on the CNC plasma cutter and let it do its job.

10. When the cutting process is complete, turn off the power to the CNC plasma cutter and disconnect all of the connections.

11. Clean up the area around the table and remove any debris that was generated during the cutting process.

12. Once everything is clean, you are ready to start using your CNC plasma table.

There you have it, the best CNC plasma tables – 2026 Buyer’s Guide. Be sure to keep the factors we’ve discussed in mind. Not all tables are created equal, and you want to make sure you get the best one for your needs. We hope our review has helped narrow down your choices and given you a better idea of what to look for when shopping for a new CNC plasma table. Thanks for reading!